Battery Recycling Solutions

Go Green, Go Power! Go Power Battery has been contributing to a healthier environment for 40+ years with lead acid battery recycling services. We make it easy for environmentally minded companies and individuals to contribute to the sustainability and protection of our natural resources. We ensure our processes are certified in order to abide by the laws and regulations set in place and use EPA-approved facilities for safe and efficient battery recycling methods. In our efforts to continue to provide the best battery recycling, we pay top dollar for your old batteries. We also offer pickup services for large quantities. If you have lead-acid batteries that need to be recycled, be sure to contact us today to see how our fast and efficient transportation services can get the job done.

Types of Battery Recycling

At Go Power Battery we recycle all types of lead acid batteries in an environmentally responsible and safe process through our closed-loop recycling efforts. We make recycling spent batteries efficient, quick and rewarding. We are your convenient solution for your battery waste.

Here are some of the most common battery types we recycle often:

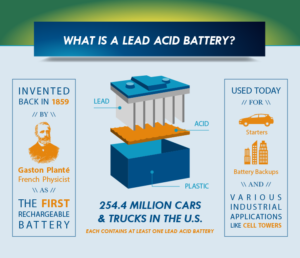

- Car and Truck Batteries- Lead acid batteries used for starting vehicles.

- Recreational batteries- Lead acid batteries used in boats, RVs golf carts, ATVs, UTVs, Personal Water Craft, kids riding toys, and Motorcycles.

- Sealed Lead Acid (SLA) -Commonly used battery for engine starting and power storage. From toys and vehicles to daily appliances, sealed lead acid (SLA) batteries, also known as valve-regulated lead acid (VRLA) batteries, power many of the products we use every day.

- UPS Batteries- Electrical storage batteries used for uninterruptible power supplies such as solar, critical power, alarm batteries, or backup lighting.

- Telecom Batteries -Often found in job-critical equipment and communications equipment.

- Industrial Batteries -Commonly found in large heavy-duty applications like machinery, forklifts, heavy equipment, floor scrubbers, stationary power, backup power, data centers, utilities, railroads, and trains.

Recycle with Us

Whether you have a low volume or one-time recycling bring your battery by today and get paid top dollar. Does your business or government agency collect or fully spend Seal Lead Acid (SLA) on a regular basis? If so, contact us to learn how we can serve you. We look forward to helping you with all of your lead acid and car battery recycling needs!

Importance of Car Battery Recycling

Recycling lead acid batteries is imperative to long-term sustainability of a healthy environment, due to the numerous negative effects they can have. Among these negative effects include accumulation of toxic lead in landfills and improper disposal leading to potential harm for those around. According to the EPA (Environmental Protection Agency), the 12-volt car battery is the most recycled product in the world. This not only helps to prevent the issues mentioned above, but it also reduces the need for new resources when building new batteries. However, improper battery recycling techniques can cause serious problems, including lead contamination. If you have car batteries that need to be recycled, Go Power Battery offers certified processes and EPA-approved facilities designed to prevent improper recycling and disposal of spent battery waste. When you work with us, you can be sure that you’re abiding to the federal and state laws surrounding battery recycling, and preventing negative effects such as lead contamination from occurring.

What is Proper Packaging of Spent Batteries?

Step 1: Select a sturdy pallet. Please note that batteries CANNOT be boxed. All batteries must be placed directly onto the pallet before wrapping and banding. Step 2: Place a layer of cardboard on the pallet to ensure that the batteries do not slide off of the pallet. The first layer of batteries must be level. Shorter batteries should be placed in the center of the layer and taller batteries should be placed on the outside of the layer. The first layer is crucial for the entire pallet to be well balanced and even. Step 3: Place an adequate layer of cardboard or honeycomb board between each layer and on the very top of the pallet. This prevents the possibility of exposed terminals and puncturing the batteries above. It is okay to stack up to 3 levels high. Step 4: Secure the batteries to the properly built pallet with shrink wrap after stacking. Make sure that the wrap connects with the bottom of the pallet as well as with the batteries. If you only wrap the batteries, there is a chance of the load sliding off of the pallet during transport. It is also helpful to use the wrap as a “rope” to pull the batteries toward the center of the pallet Step 5: Ensure that all outer surfaces are wrapped thoroughly and band the wrapped pallet. We recommend a minimum of 3 layers of wrap around the entire surface. A minimum of 3 horizontal bands and 3 vertical bands around the palletized cells is also recommended to prevent the batteries from shifting during transport. Banding should be a minimum of 5/8 inch wide.

Other Packaging Guidelines:

- DOT Regulations require that batteries be properly packaged and loaded to prevent short circuits in transit.

- Keep batteries upright at all times.

- Batteries with side terminals should not be in contact with other side terminals to prevent short circuits in transit.

- No metals can be in contact with battery terminals.

- Remove all attachments from batteries, including cables, to prevent short circuits or sparking.

- Damaged or leaking batteries must be shipped in DOT-approved containers with lids and secured to pallets. Plastic bags are not acceptable.

- No bulk acid may be shipped.

- Batteries cannot be shipped in boxes or racks or an additional tare deduction will be made.

- All batteries must be placed directly onto the pallet before wrapping and banding.

- Gaylord boxes are acceptable for shipping and should be no more than 3 layers high with cardboard between each layer and on the top layer. Gaylord boxes must be securely banded to prevent breaking and shifting during transport.

- All battery caps must be in place or use foam to replace missing caps.

- Do not double-stack pallets.